Release time:2024-06-19

At present, the proportion of plastic mold in the whole mold industry is about 30%, and the proportion in mold import and export is as high as 50-70%. In recent years, plastic molds have developed rapidly in China, and plastic products are more and more widely used, providing a broad market for plastic molds.

The overall trend of molds is stable and rising. In the future mold market, the development speed of plastic molds will be higher than that of other molds, and the proportion in the mold industry will gradually increase. Among them, plasticMold processingThe process generally presents the following development trends:

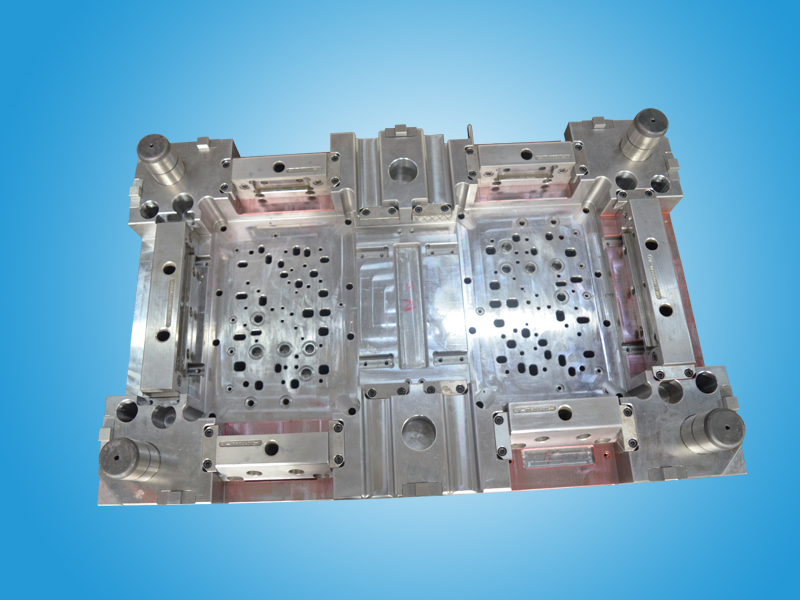

1. The scale of mold forming parts is becoming larger and larger and the productivity of parts is high, which requires multiple cavities in one mold, resulting in the larger and larger scale of molds. Large tonnage large molds can reach 100 tons, hundreds of cavities and thousands of cavities in a mold. Mold processing equipment is required to have a large workbench, larger Y-axis and z-axis travel, large load-bearing, high rigidity and high consistency.

2. The die steel used has high hardness, which requires the die processing equipment to have thermal stability and high reliability.

3. For complex cavities and multi-functional composite molds, with the complexity of the shape of parts, it is necessary to improve the design and manufacturing level of molds. The multifunctional composite mold of various grooves and materials formed or assembled into parts in a set of molds requires a large number of processing programming programs, and has the comprehensive cutting ability and high stability of high deep hole cavity, which improves the processing difficulty.

4. The refinement of mold processing makes the complexity and efficiency of processing equipment more attractive. High speed milling has many advantages, such as machining high hardness materials, processing stability, small cutting force, small workpiece temperature deformation and so on, which makes mold enterprises pay more and more attention to high-speed machining.

5. High dynamic accuracy. The static performance introduced by the machine tool manufacturer cannot reflect the actual processing situation when processing the three-dimensional mold surface. The high-precision machining of the three-dimensional surface of the mold requires high dynamic precision performance. Only by matching the high rigidity, thermal stability, high reliability and high-quality control system of the machine tool, can we achieve high speed and high precision.